Medical Disposables

Our tooling and molding experience enables us to produce an array of one-time use products such as syringes. Working with you, we can design and deliver tight tolerances using the materials appropriate for stringent biomedical and healthcare application. Our decades of experience enable us to develop injection-molded components based on what we know works or carefully vet and design new tooling for a solution. Regardless of the material or application, we have the knowledge of every type of material to develop and design your critical-to-life product.

Drug Delivery

Our designers, engineers, and staff draw on their experience to produce injection molded plastic parts for critical drug-delivery systems. With our know-how and streamlined processes, we can strike a balance between creating quality designs, keeping your costs in check, and producing a high-performance component. We do it by continually boosting our technology and skills. Our technologies include:

- insert molding,

- micro injection molding,

- multi-component injection molding, and more.

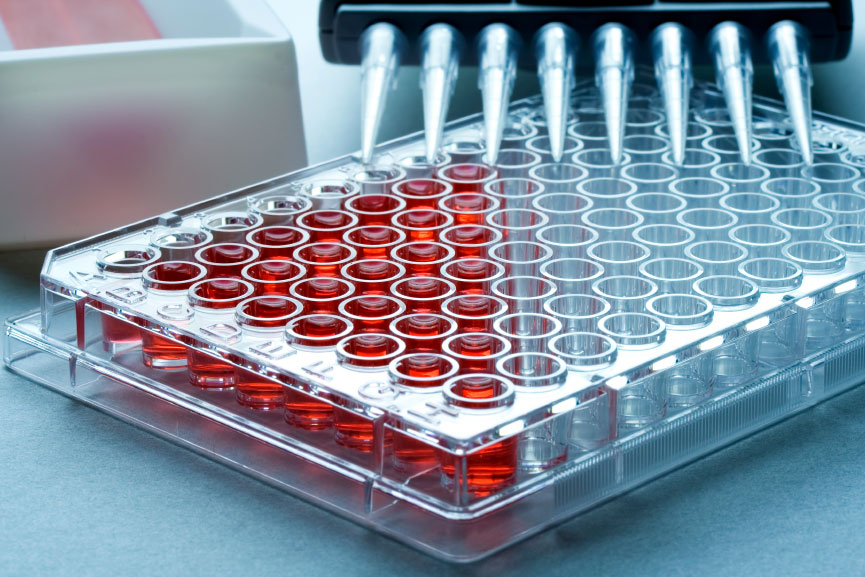

Medical Device

Whether the application is emergency care or labware, we can manufacture Class I, II, and III components and devices with the type and kind of material that is best suited for the job to be done. As a team, we have built and managed several companies dedicated to medical device injection molding. We understand scientific molding principles and quality control, so we know what it takes to create first-class injection molded components. We also help you produce premium products in a way that is profitable.

From orthopedics to home healthcare devices, we provide Certified ISO-7 and ISO-8 clean manufacturing environment assembly and packaging to complement our medical device injection molding process. Along with assembly and packaging, we provide quality control and inspection.

Healthcare Packaging

With our knowledge of healthcare packaging standards, we can deliver high-quality, creative solutions that also meet the requirements of the healthcare and biosciences industries. Whether you want to produce pill bottles, specialty packaging, vitamin packs or something in between, our design, technology, and workmanship will produce a superior component.

Our degreed engineers and RJG Master Molder® qualified technicians and managers understand healthcare and biosciences mold qualifications in relation to installation qualification, operational qualification, and performance qualification, or IQ/OQ/PQ. Our know-how extends from working with engineering-grade resins to custom medical packaging. All this spells one thing for you: Receiving a top-notch product on time, on budget.

Pharmaceutical Disposables

Our experts specialize in prototyping and producing tooling for high-volume disposables and unit-dose packaging for a wide array of applications. We use engineering-grade plastics in our injection-molding processes to create components that comply with the FDA and keep the safety of patients front and center.

The plastic-injection molded components we develop are made from engineering-grade plastic resins to ensure high-quality mechanical properties like temperature resistance and tensile strength. Our knowledge of materials science allows us to help you select materials for your pharmaceutical disposables that meet the requirements of general use, government and medical standards, and a level of strength for the application.